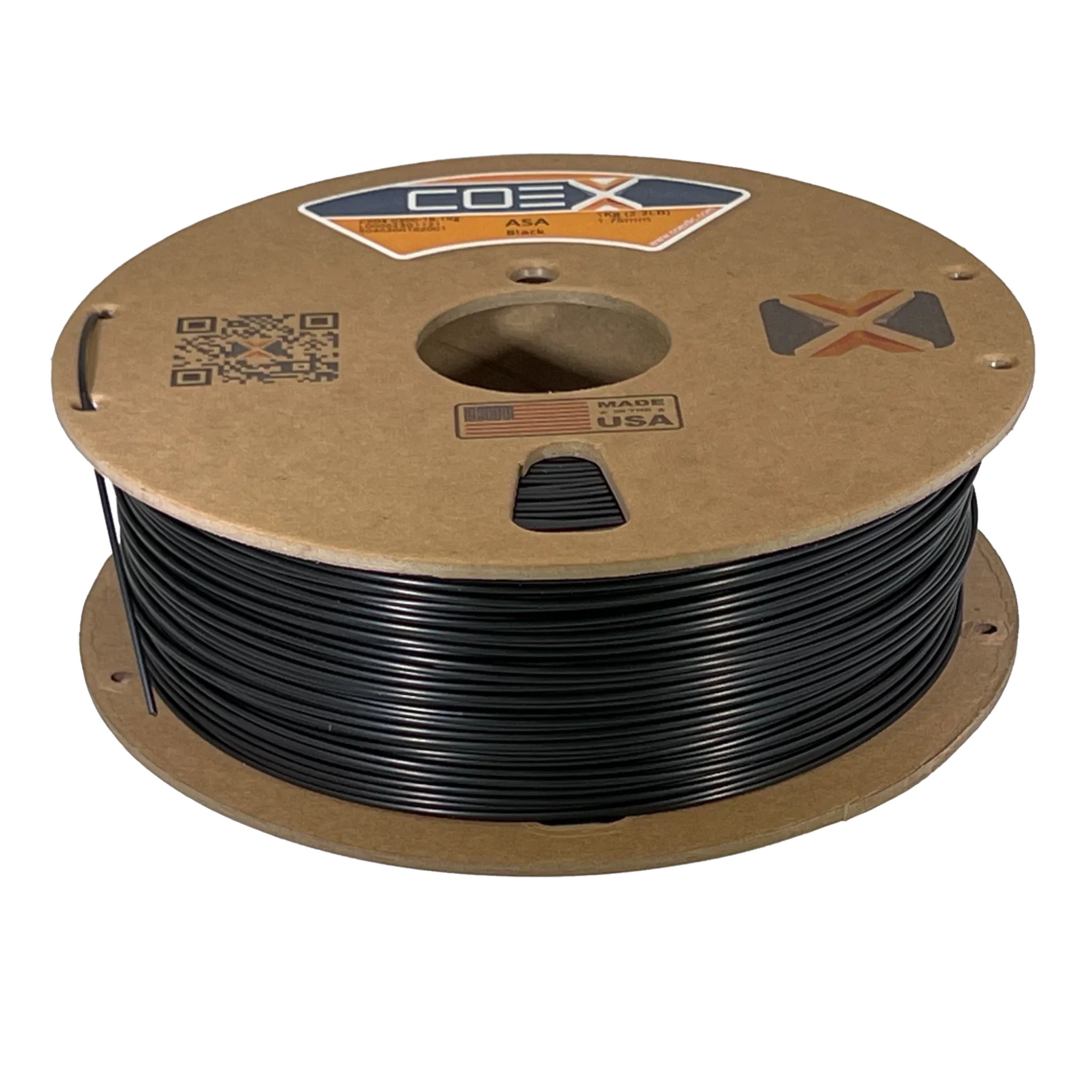

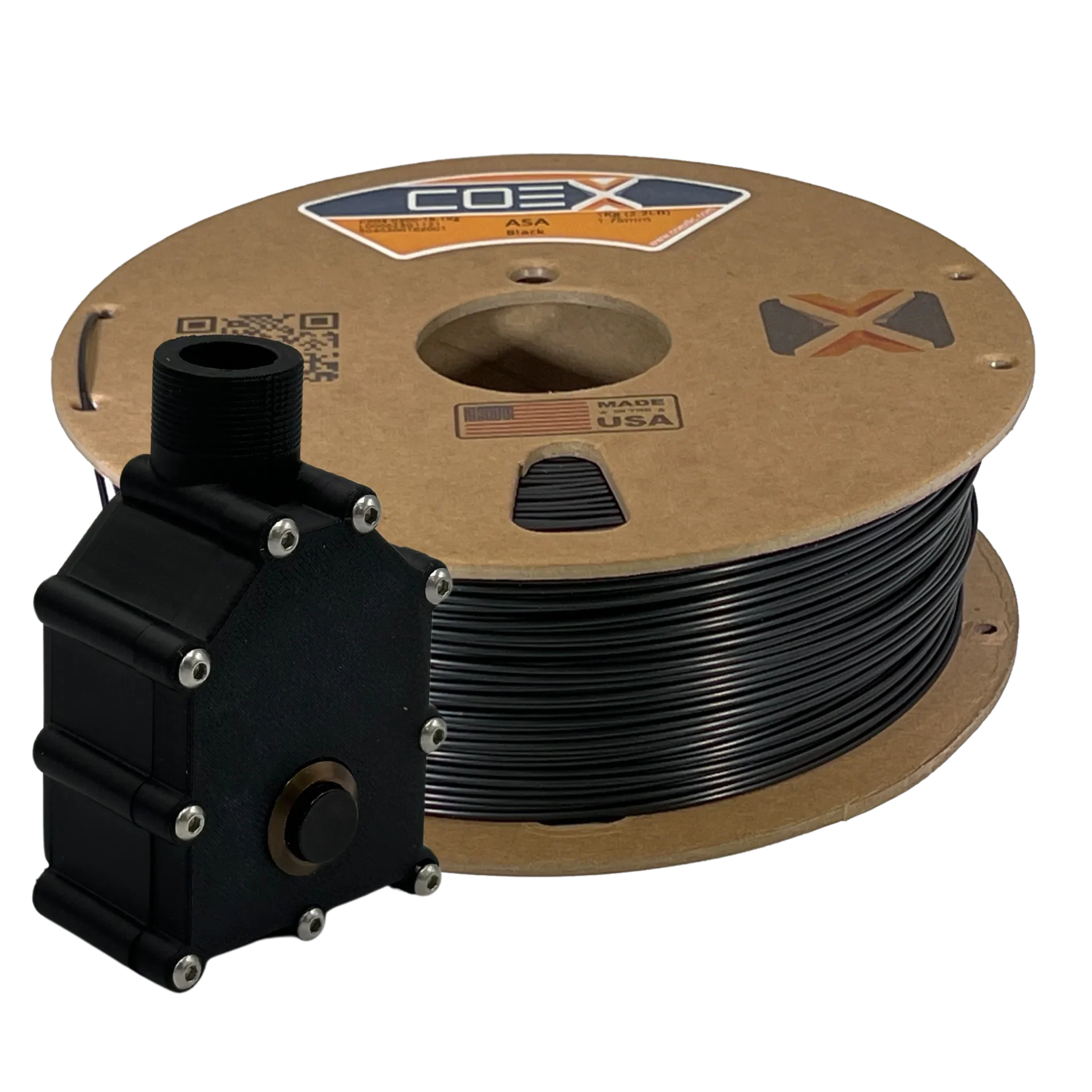

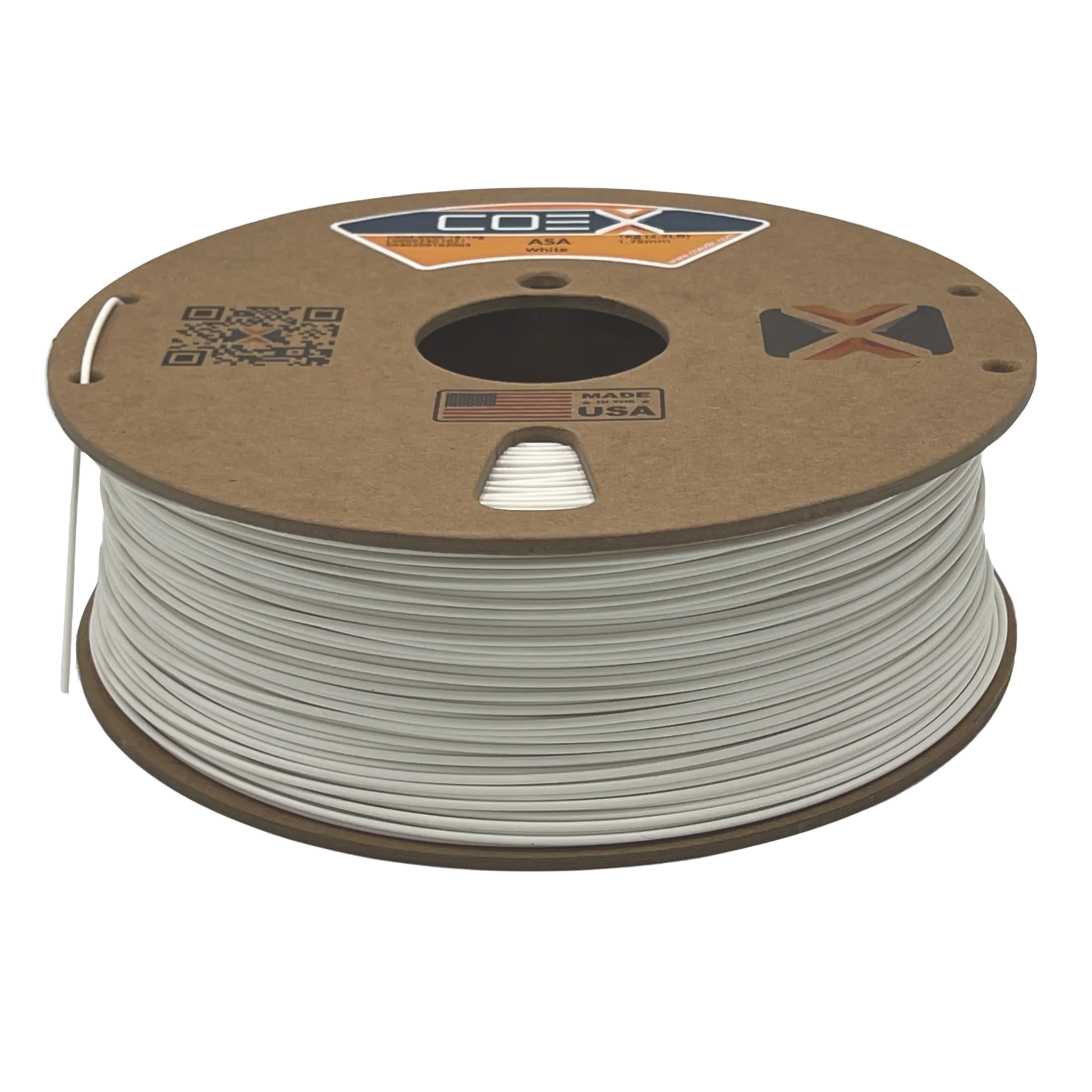

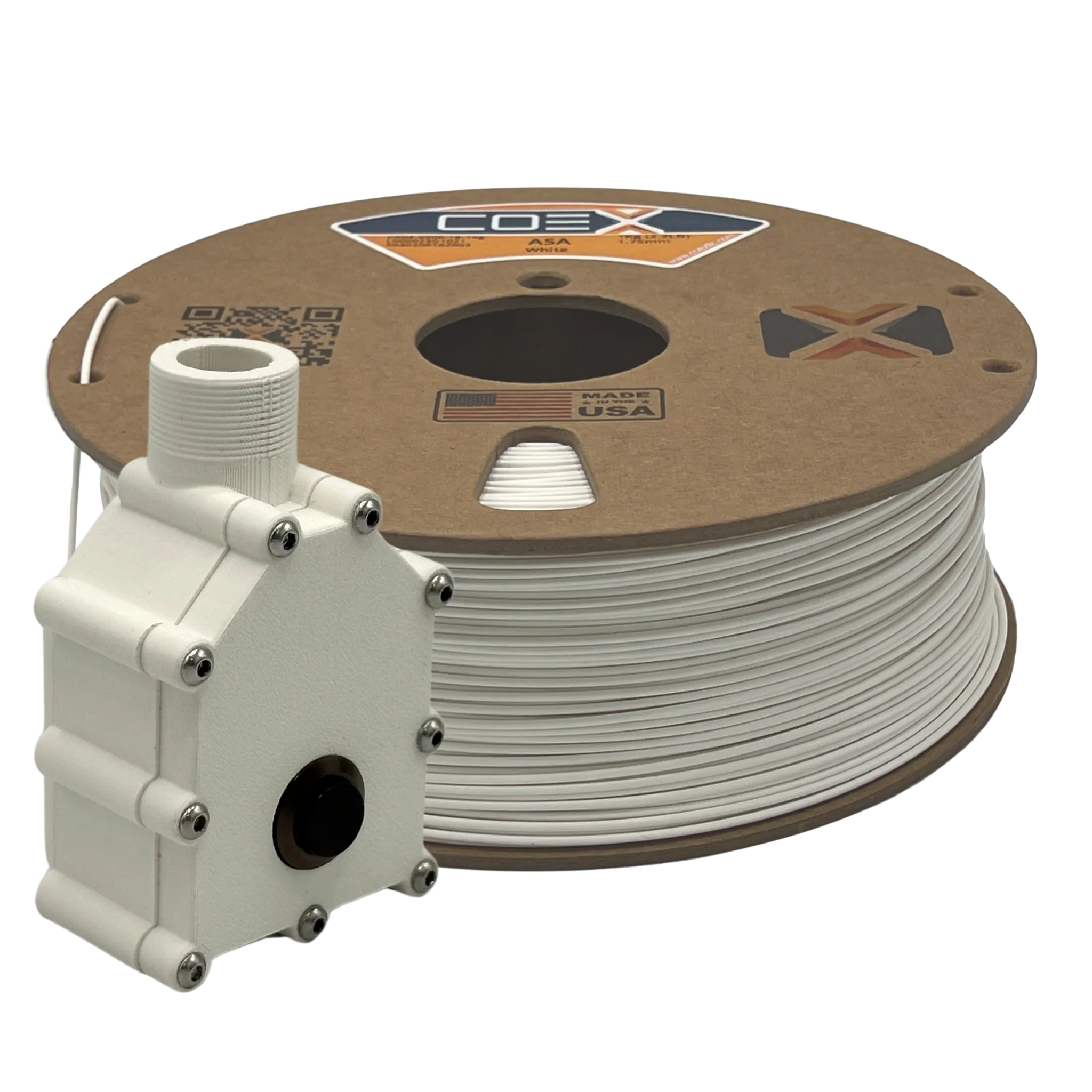

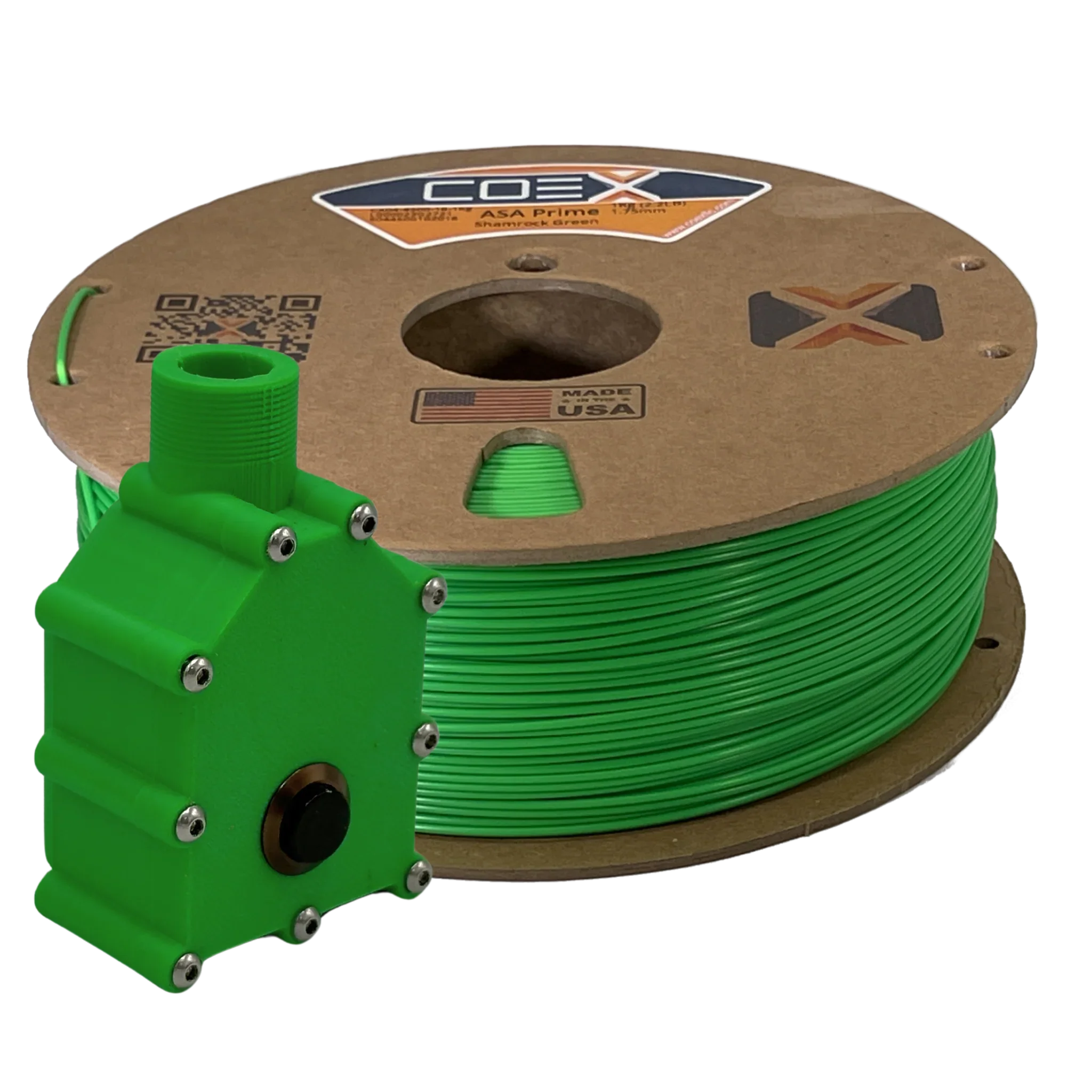

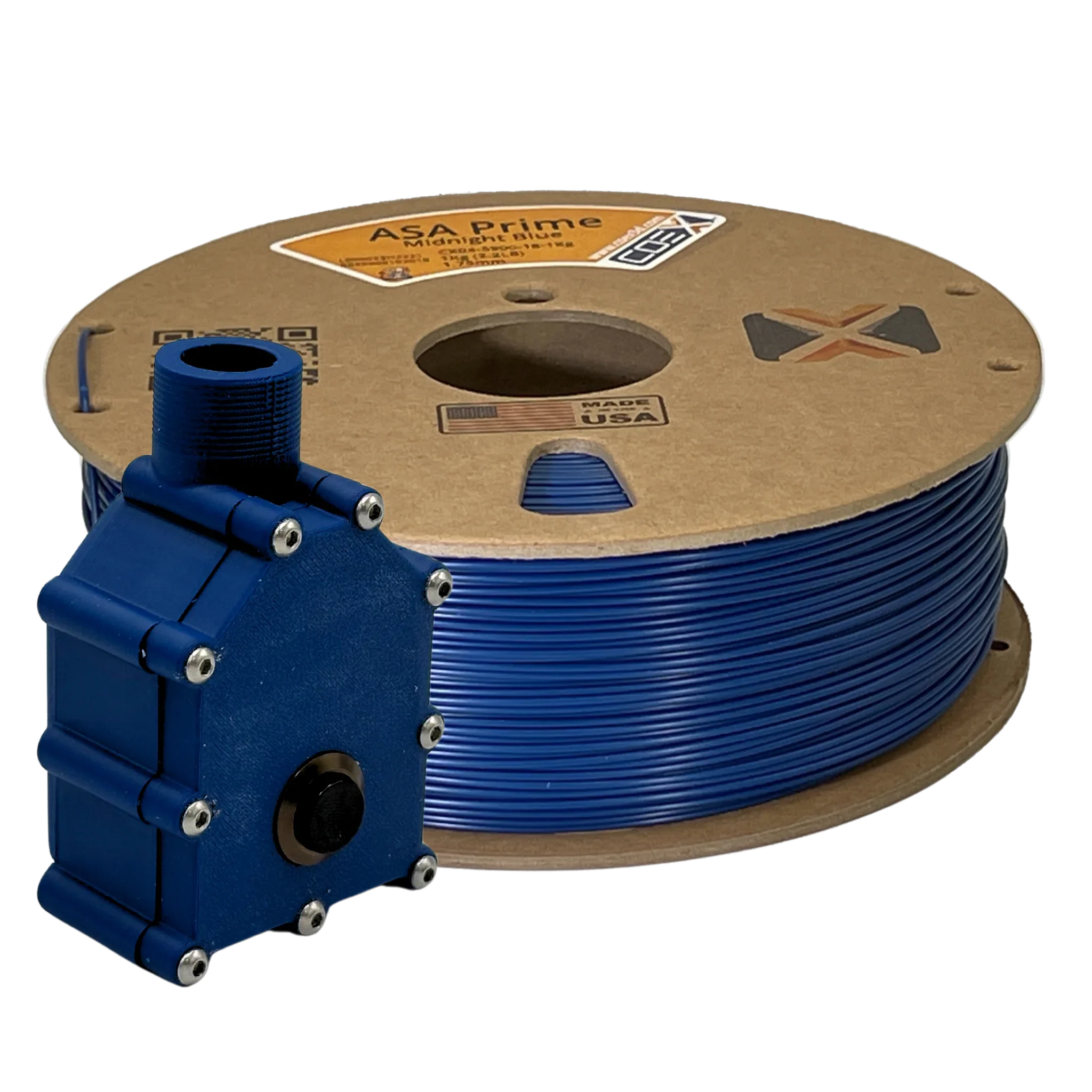

ASA Prime

14 products

Showing 1 - 14 of 14 products

Showing 1 - 14 of 14 products

Display

View

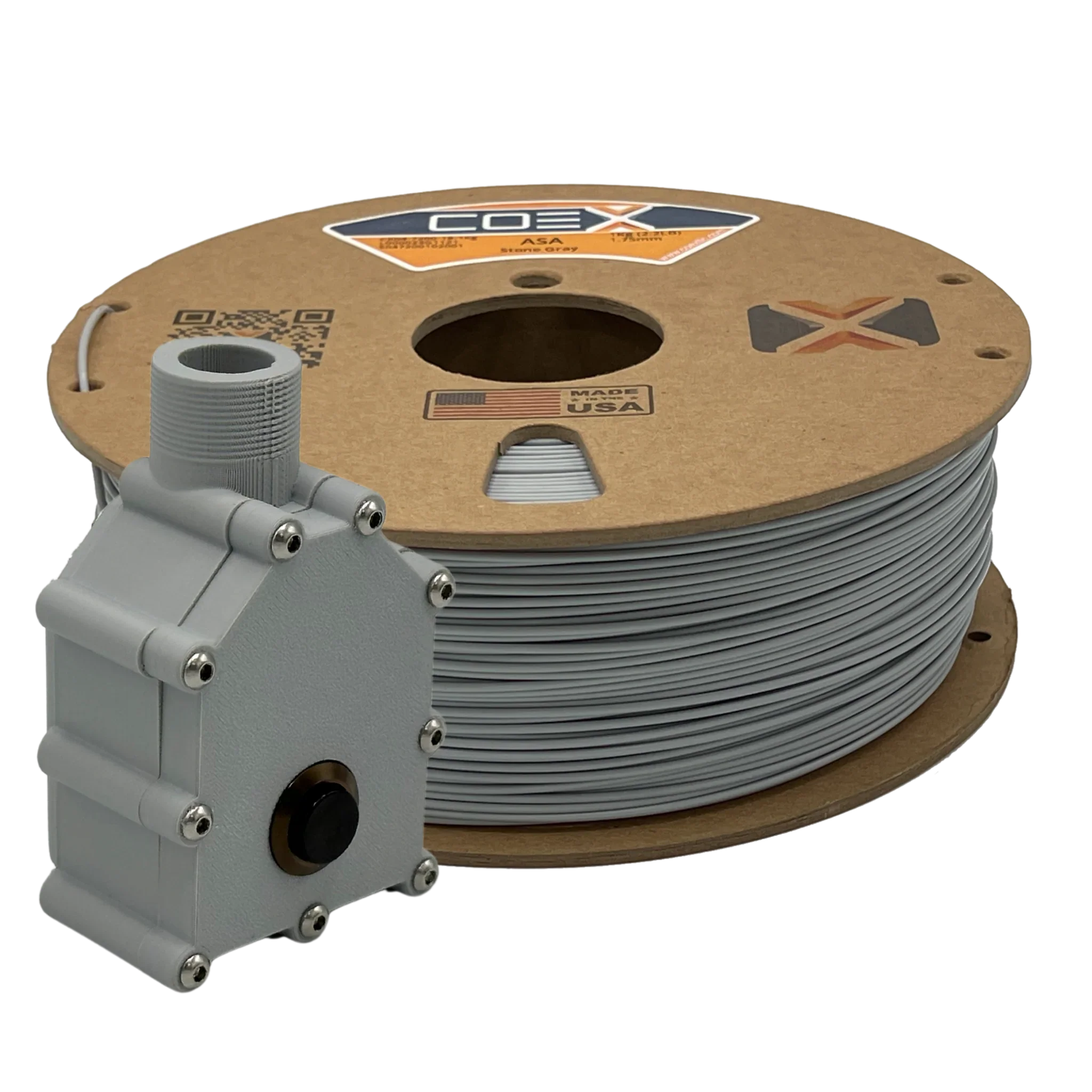

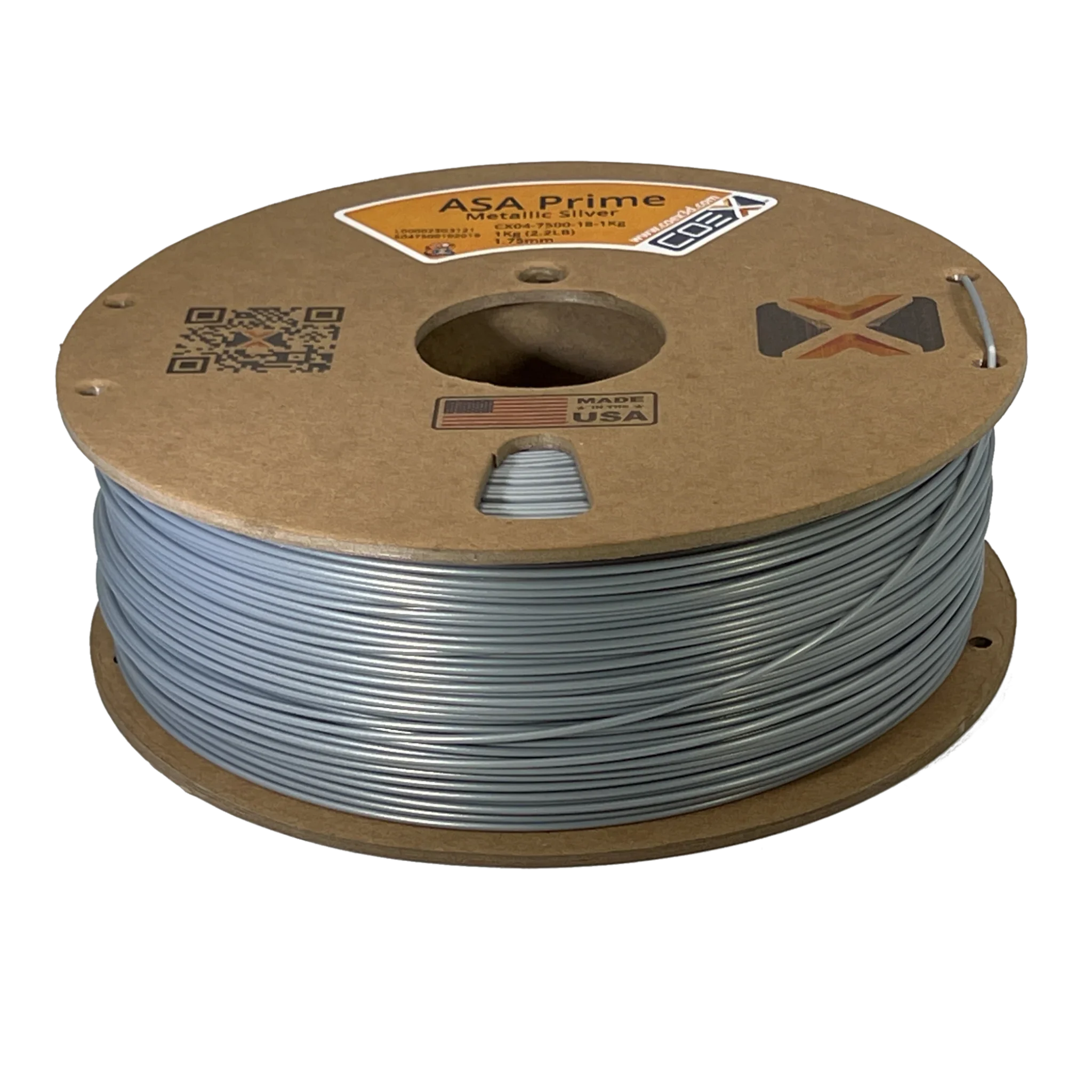

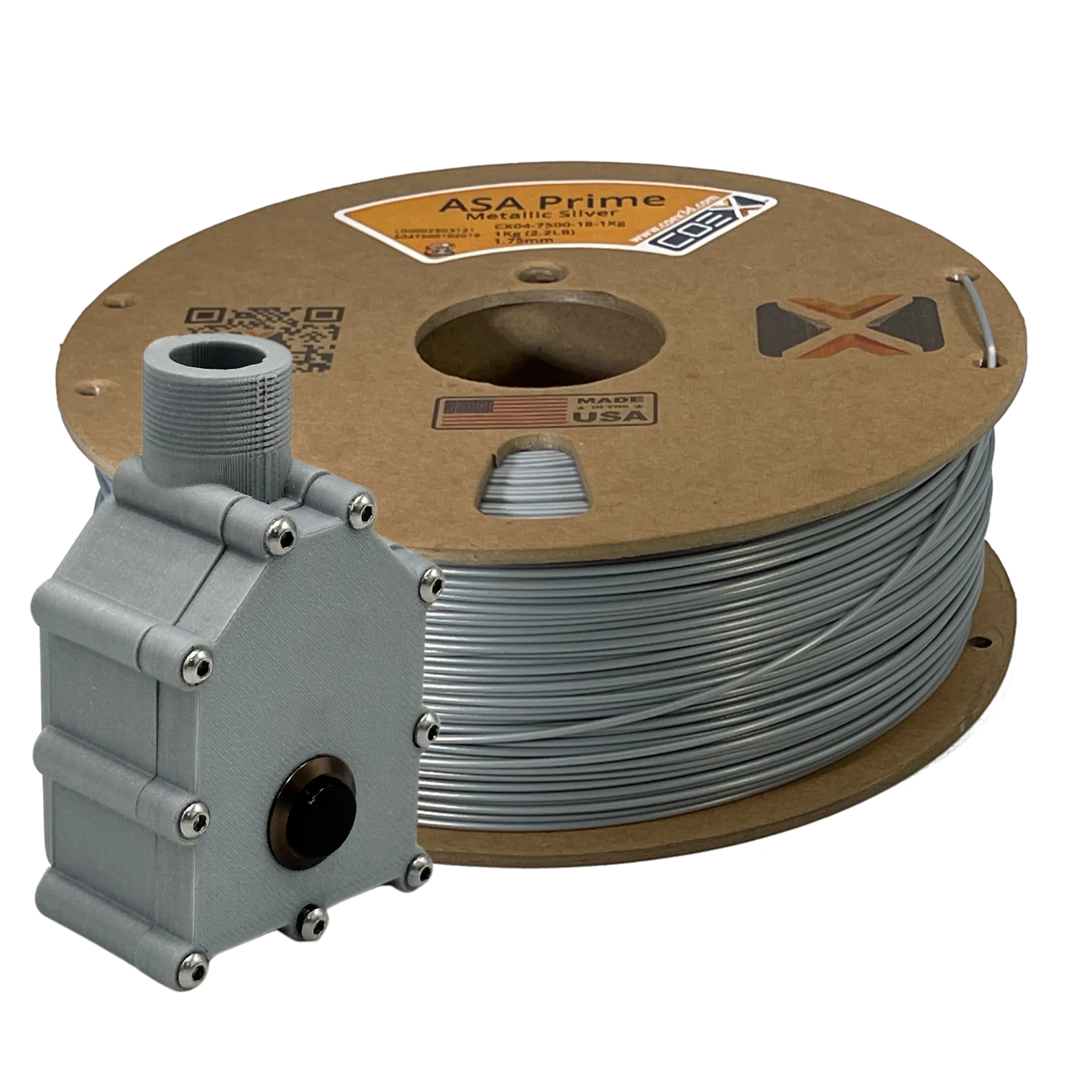

Metallic Silver ASA Prime

Sale priceFrom $21.00

{"other"=>"Stock: {{count}}, We will be making more soon"}

Filters (0)