Infill for FDM 3D Printing

Josh BonninShare

FDM 3D printed parts are not always made solid. Rather, with this printing method, parts can be made varying degrees of hollow to help control the print time, cost, and weight of the part. This is done by altering the infill percentage of a part on the FDM 3D printer. Other 3D printing technologies do not have this feature, and to achieve a similar effect, infill must be manually made into the design’s CAD file before sending it to the printer.

In this article, we’ll cover what infill is and why it’s beneficial, as well as types of infill patterns and whether a higher or lower infill percentage is better suited for your part.

What is Infill?

With FDM, each layer is made up of a boundary and infill. The boundary, or shell, is the external surface that is visible on the completed part. The infill is the internal structure of the part that cannot be seen. For infill, filament is extruded in a repeating pattern that can help boost the strength of a part.

Infill density can range from 0% (hollow) to 100% (solid) and greatly controls the print time, cost, and weight of the final part. By changing how dense the infill of your part is, you can better control these aspects of your project and help ensure you meet deadlines, stay within budget, and aren’t sacrificing part strength.

The percentage of infill density you need may also depend on your part’s application. For instance, the shell of a part can be designed thicker to help improve part strength for a high-stress environment, but for some designs, a thin shell may be necessary. By adding infill, the shell can be supported so it can endure more stress than if the part were hollow. Infill can also help the machine to print over empty space with more reliability, making the part more stable.

For quick reference, here is a breakdown of lower versus higher infill percentages to consider when determining the amount of infill your part will need:

Lower Infill Percentage

- Less material used

- Lower cost

- Quicker print time

- Lighter weight

- Greater transparency with clear filament

- Can be fragile (best for models)

Higher Infill Percentage

- More material used

- Higher cost

- Longer print time

- Heavier

- Stronger snap-fit features

- Screws have more grip and create stronger connections

- 100% solid infill gives the most strength (best for functional parts)

Ideally, you should find the infill percentage that gives your part sufficient strength without overdoing it so time and cost can be minimized.

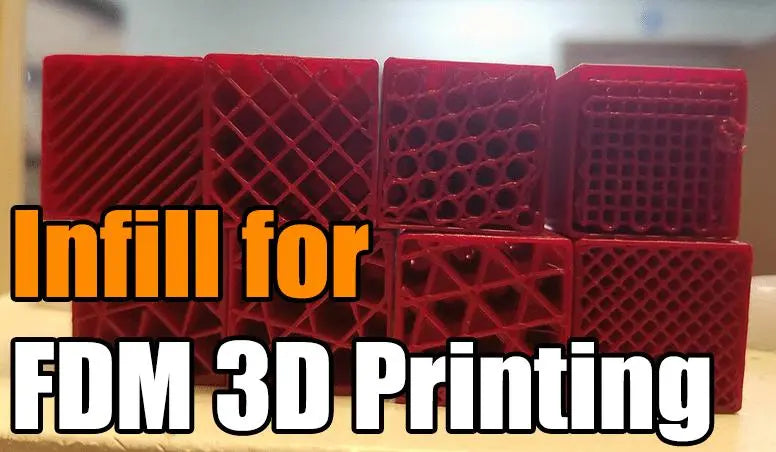

Types of Infill Patterns

As mentioned above, infill is constructed of a repeating pattern on the inside of the part. There are several different options for these patterns, and each has structural benefits that can aid in the stability of your part. Here are the four most commonly used infill patterns:

Rectangular

A rectangular infill pattern is the default for many FDM 3D printers. Due to its block structure and perpendicular layers, it enforces strength in all directions while remaining quick to print. Not a lot of bridging across the pattern is required when using this infill style.

Triangular

Triangular, also known as diagonal infill, is used when seeking to elevate strength in the direction of the part’s walls. Higher strength is achieved because the lines that make up the pattern apply force at a 60° angle. This type of infill takes a bit longer to print than standard rectangular.

Honeycomb

Honeycomb, or hexagonal infill, is a popular infill type similar to rectangular infill in that it provides strength in every direction. It takes a bit longer to print but is beneficial for parts that need greater strength than rectangular can offer, such as carbon fiber parts.

Wiggle

The wiggle infill pattern differs from the other three on this list in that it does not use intersecting lines to add support. Rather, the wiggle infill looks like wavy or zigzag lines. This pattern is primarily used for flexible filaments, such as softer nylon or other such rubbery filaments, where parts are designed to twist or compress and must have a rebound force. This infill can still provide support to perpendicular walls.

1 comment

Great information on infill patterns! This blog explains FDM 3D printing techniques clearly and helps improve print strength and efficiency.