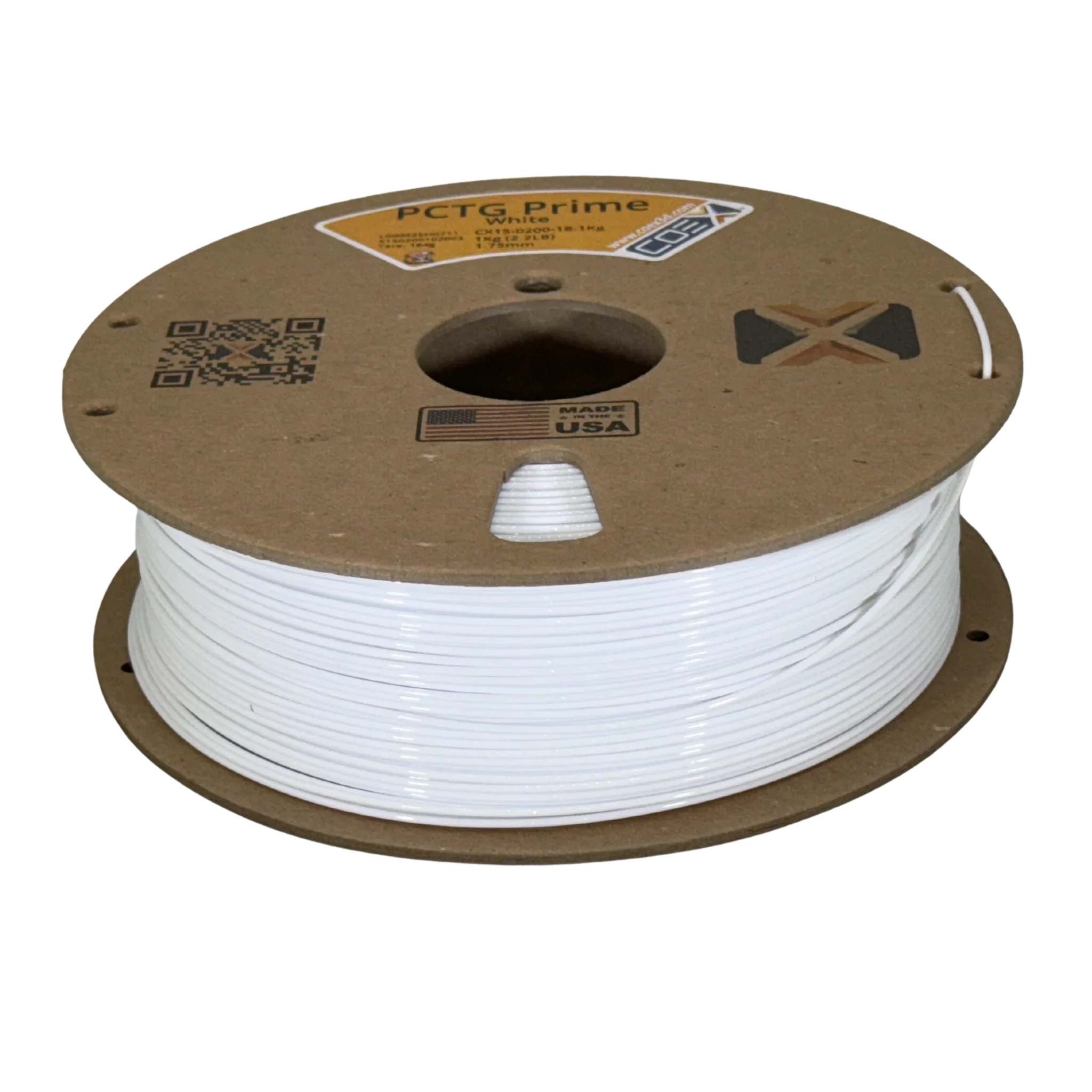

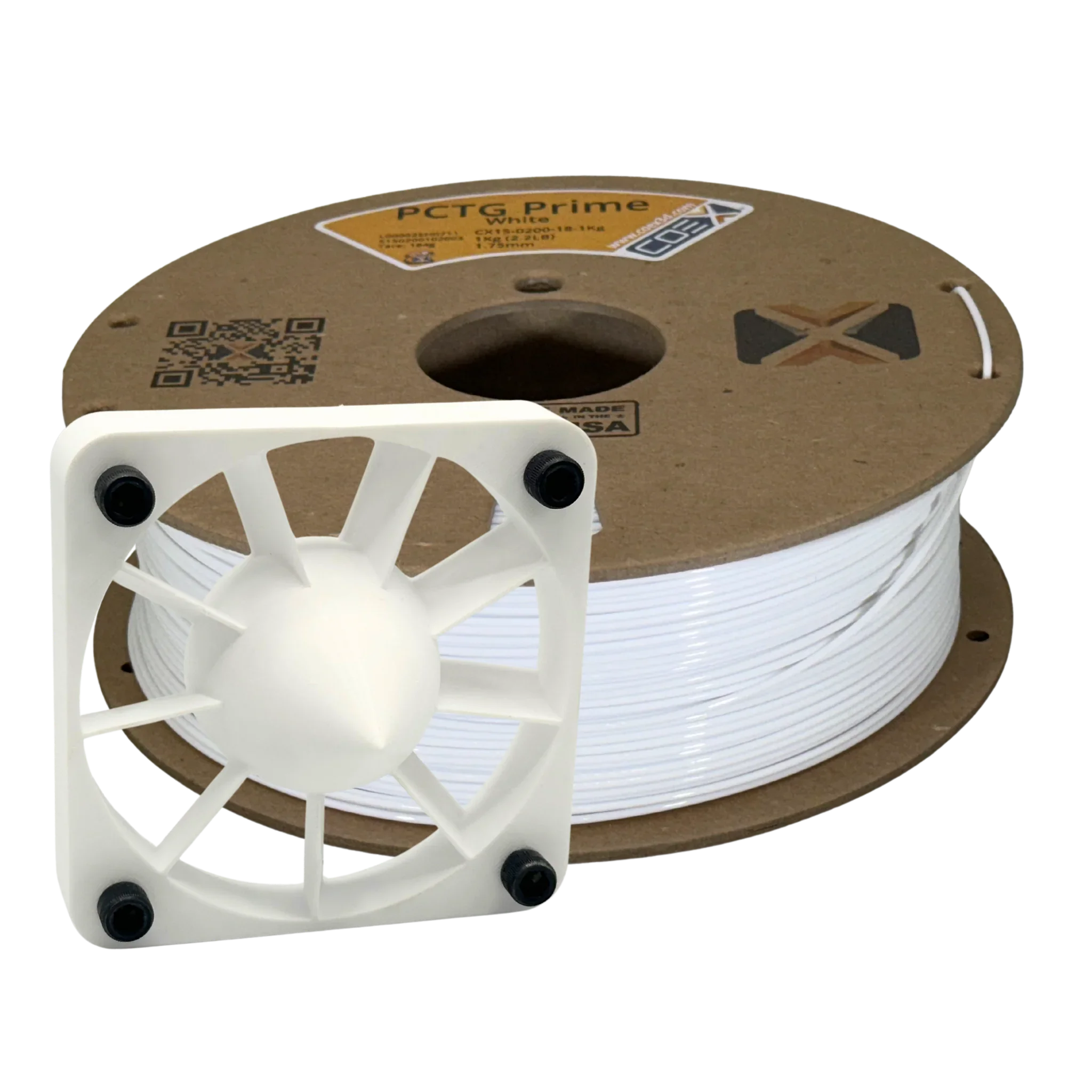

Technical Printing Guide - COEX PCTG

1. Material Notes

- Keep filament dry - store properly and dry before use

- If needed, dry at 65°C for 3 hours or more

- Enclosure is helpful but not mandatory

- Use Z-offset slightly higher than PLA (+0.05mm)

- Enable "Avoid crossing perimeters" to reduce stringing

- Consider using the "Wipe while retract" option

- Enable "Slow down for small perimeters."

- Print outer walls slower for better quality

- Use a minimum layer time of 30 seconds for small parts

- Enable cooling gradually after the first layer

- Consider using "Extra Prime Amount" after retraction

2. Temperature Settings

Bed Temperature: 70-90°C

- Wash the bed often for good adhesion - Use dish soap and rinse thoroughly to remove oils

- Use bed adhesion products if necessary (gluestick, WELD3D)

- Use brim for tall or large prints

- Keep the ambient temperature stable

Extruder Temperature: 240-275°C

3. Basic Parameters

| Nozzle | Layer Height | Line Width | Volumetric Speed | Temperature |

| 0.4mm | 0.2mm | 0.42mm | 14.0 mm³/s | 245°C |

| 0.6mm | 0.3mm | 0.62mm | 31.5 mm³/s | 245°C |

| 0.8mm | 0.4mm | 0.82mm | 56.0 mm³/s | 250°C |

| 1.0mm | 0.5mm | 1.02mm | 87.5 mm³/s | 265°C |

4. Speed Settings

0.4mm Nozzle (Volumetric Speed: 14.0 mm³/s)

| Line Type | Percentage | Speed |

| External Perimeter | 50% | 83.33 mm/s |

| Internal Perimeters | 75% | 125.00 mm/s |

| Infill | 100% | 166.67 mm/s |

| Top/Bottom | 60% | 100.00 mm/s |

| First Layer | 30% | 50.00 mm/s |

0.6mm Nozzle (Volumetric Speed: 31.5 mm³/s)

| Line Type | Percentage | Speed |

| External Perimeter | 50% | 84.68 mm/s |

| Internal Perimeters | 75% | 127.02 mm/s |

| Infill | 100% | 169.35 mm/s |

| Top/Bottom | 60% | 101.61 mm/s |

| First Layer | 30% | 50.81 mm/s |

0.8mm Nozzle (Volumetric Speed: 56.0 mm³/s)

| Line Type | Percentage | Speed |

| External Perimeter | 50% | 85.37 mm/s |

| Internal Perimeters | 75% | 128.05 mm/s |

| Infill | 100% | 170.73 mm/s |

| Top/Bottom | 60% | 102.44 mm/s |

| First Layer | 30% | 51.22 mm/s |

1.0mm Nozzle (Volumetric Speed: 87.5 mm³/s)

| Line Type | Percentage | Speed |

| External Perimeter | 50% | 85.78 mm/s |

| Internal Perimeters | 75% | 128.68 mm/s |

| Infill | 100% | 171.57 mm/s |

| Top/Bottom | 60% | 102.94 mm/s |

| First Layer | 30% | 51.47 mm/s |

5. Retraction Settings

IMPORTANT: Set travel speed to the maximum your machine allows (200-500mm/s). Faster movements reduce filament oozing time, minimizing stringing.

| Nozzle | Distance | Speed | Z-Hop |

| 0.4mm | 1.0-1.5mm | 40mm/s | 0.2mm |

| 0.6mm | 1.0-1.5mm | 40mm/s | 0.2mm |

| 0.8mm | 1.0-1.5mm | 40mm/s | 0.2mm |

| 1.0mm | 1.0-1.5mm | 40mm/s | 0.2mm |

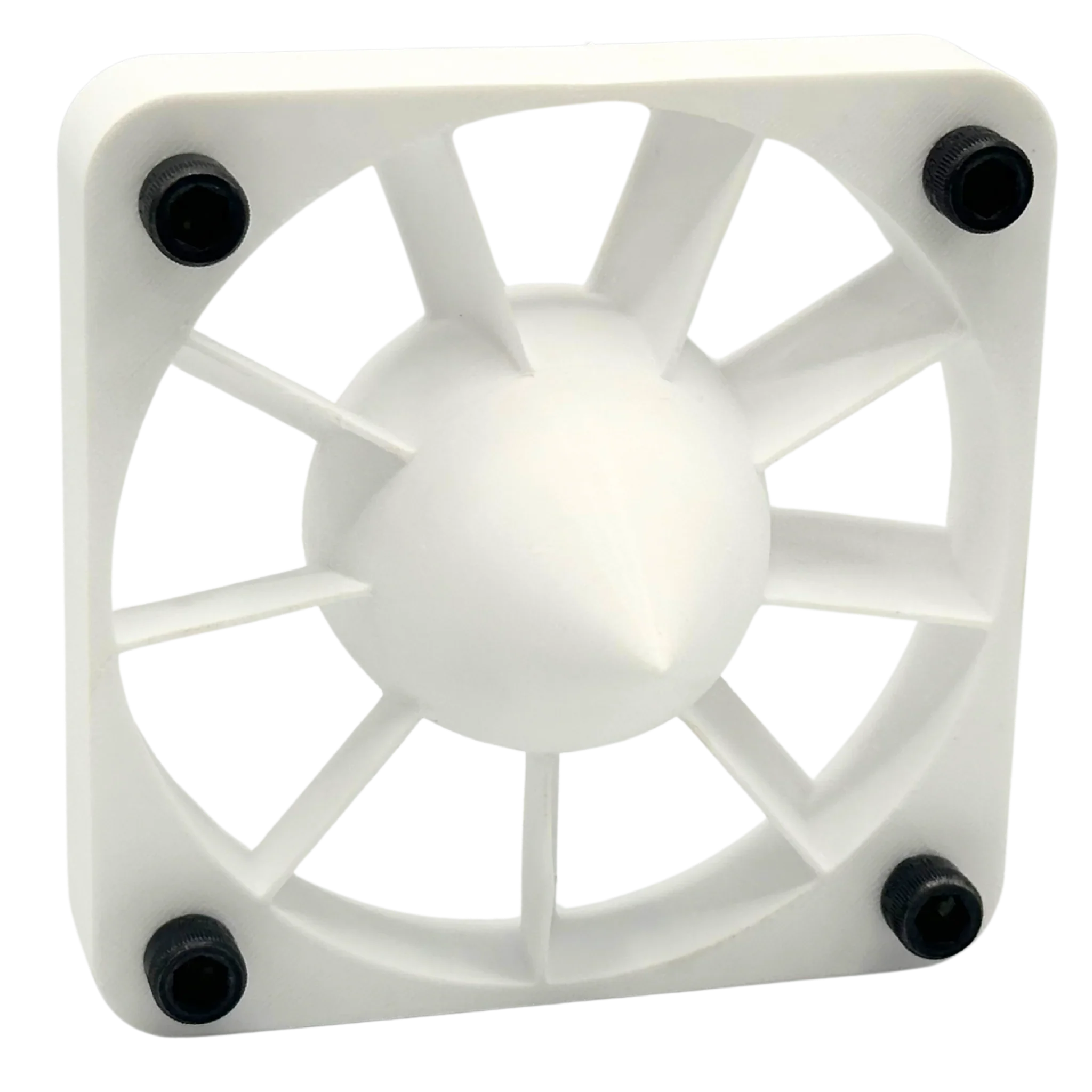

6. Cooling Settings

Cooling Configuration:

Fan Speed Settings:

- First Layer: 0% (fan off)

- General Printing: 40% fan speed

- Bridges and Overhangs: 70% fan speed

- Layers < 30 seconds: 70% fan speed

Advanced Settings:

- Keep Fan Always On: YES

- Force Fan Speed for Overhangs: YES

- Minimum Layer Time: 30 seconds

- Force Fan Speed for Small Perimeters: YES

Additional Cooling Notes:

- Enable gradual fan speed increase after the first layer

- Increase fan speed for small, detailed parts

- Consider reducing fan speed for better layer adhesion if needed

- Monitor overhangs and bridge quality to adjust fan speed

7. Troubleshooting Guide

| Problem | Solution |

| Irregular extrusion |

1. Dry the filament 2. Check the extruder 3. Reduce speed |

| Poor adhesion |

1. Dry the filament 2. Use adhesive 3. Adjust the first layer |

| Stringing |

1. Dry the filament 2. Adjust retraction 3. Increase travel speed 4. Check temperature |

PLEASE NOTE: These printing parameters are initial recommendations based on our experience. They may need adjustment depending on your specific 3D printer, environmental conditions, and the geometry of the part you are printing. Use these settings as a starting point and fine-tune them according to your specific needs.