Material Safety Data Sheet: CX23 PA6CF SERIES 3D PRINTING FILAMENT

MSDS

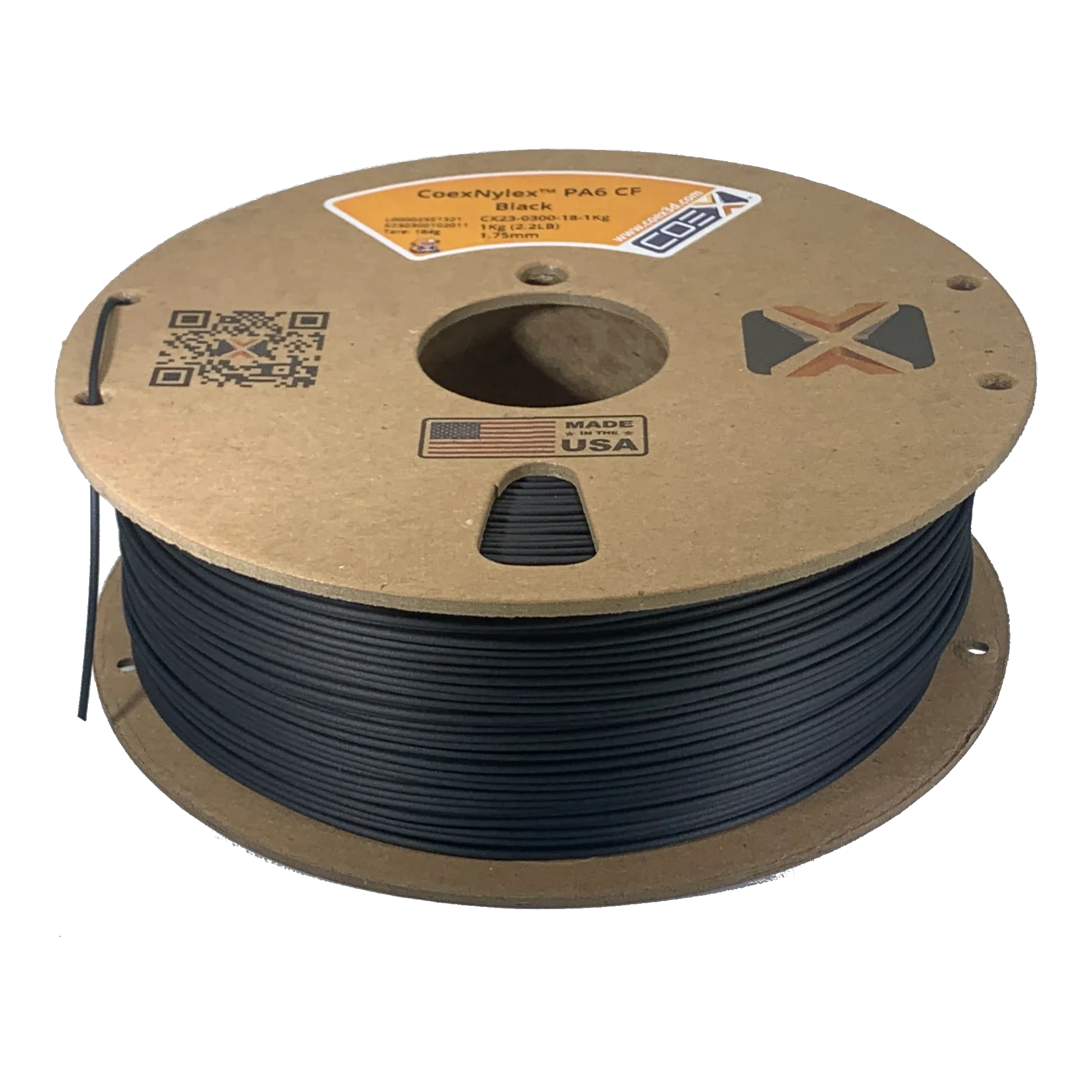

BASE RESIN: COEXNYLEX PA6CF

Issue Date: 05-12-2025

1. Identification of the substance/preparation of the company

1.1 Trade name:COEXNYLEX PA6CF 3D printer filament

1.2 Use of the product:3D printer filament, thermoplastic.

1.3 Supplier:1228 Elizabeth St

Green Bay, WI 54302

Phone: (920) 757-1055

2. Hazards identification

2.1 Classification:The product is not considered hazardous by 2012 OSHA Hazard Communication Standard: 29 CFR 1910.1200

2.2 Special advice on hazards:No specific dangers known.

3. Composition / information on ingredients

| Chemical name | CAS No. | Weight % | Proprietary |

|---|

| Unspecified Nylon | * | 70-95 | * |

| Carbon Fiber | 7440-44-0 | 5-30 | |

The product contains no substances which at their given concentration are considered to be hazardous to health.

4. First-aid measures

4.1 On skin contact:In case of contact with molten polymer immediately cool the skin with cold water. Medical aid may be required to remove adhering material and for treatment of burns. The material is not likely to be hazardous by skin contact, but cleaning the skin after use is advisable.

4.2 After inhalation:Remove from exposure and move to fresh air immediately. If not breathing, give artificial respiration. If breathing is difficult, give oxygen. Get medical aid.

4.3 On ingestion:Drink plenty of water. Do not induce vomiting without medical advice. Call a physician immediately.

4.4 On eyes contact:In case of contact, immediately flush eyes with copious amounts of water for at least (15) minutes.

5. Fire-fighting measures

5.1 Suitable fire extinguishing media:Water spray, foam, dry powder.

5.2 Special exposure hazards:Hazards during fire-fighting: Ammonium hydroxide, carbon monoxide, carbon dioxide, hydrocarbons, nitriles, and hydrogen cyanide can be emitted at > 320 °C.

5.3 Special protective equipment:Self-contained breathing apparatus

5.4 Remark:In case of fire and/or explosion do not breathe fumes.

6. Accidental release measures

6.1 Personal precautions:Spilled material may cause a slipping Hazard.

6.2 Methods for cleaning up:Vacuum or sweep up material and place into a suitable disposal container.

7. Handling and storage

7.1 Handling:Avoid contact with molten polymer. Avoid inhalation of dusts/mists/vapors.

7.2 Storage:Protect against moisture. Store cool and keep packaging closed when not in use. Avoid sources of ignition.

8. Exposure controls/ personal protection

8.1 Technical safety measures:This product, as supplied, does not contain any hazardous materials with occupational exposure limits established by the region-specific regulatory bodies.

8.2 Personal safety equipment:Use adequate safety equipment, e.g. protective clothing, eye protection glasses, heat protection gloves. Additives in this product do not present a respiration hazard unless the product is ground to a powder of respirable size and the dust is inhaled. All dusts are potentially injurious to the respiratory tract if respirable particles are generated and inhaled. A respiratory protection program that meets country requirements must be followed whenever workplace conditions warrant respirator use. Consult the respirator manufacturer to determine the appropriate type of equipment for a given application. Observe respirator use limitations specified by the manufacturer. Consult the OSHA respiratory protection information located at 29CFR 1910.134. Use a positive pressure air supplied respirator if exposure levels are not known or there are any other circumstances where air purifying respirators may not provide adequate protection.

8.3 Work hygiene:No eating or drinking during working. Avoid contact of hot material with the skin. Avoid breathing dust and vapors.

9. Physical and chemical properties

9.1 Form:Spool

9.2 Color:Various

9.3 Odor:None

9.4 Melting Temperature:195C

9.5 Oxidizing properties:No test data

9.6 Explosions limits:No test data

9.7 Density:1.18 g/cm³

9.8 Solubility in water:Not soluble

10. Stability and reactivity

10.1 Stability:The product is stable at recommended storage conditions.

10.2 Conditions to be avoided:Temperature: > 320 degrees Celsius

10.3 Substances to be avoided:No special recommendations.

10.4 Hazardous decomposition products:Hazardous decomposition products: Ammonium hydroxide, carbon monoxide, carbon dioxide, hydrogen cyanide, nitriles. Thermal decomposition: > 320 °C

11. Toxicological information

11.1 Local irritation:None

11.2 Other remarks:Assessment of irritating effects: Irritation is possible when the product comes in contact with the skin, respiratory tract or the eyes. Thermal decomposition products of the substance can irritate the eyes, skin, and respiratory tract.

12. Ecological information

12.1 Ecological info:The product has not been tested. There is a high probability that the product is not acutely harmful to aquatic organisms.

12.2 Biological degradation:Experience shows this product to be inert and non-degradable. The product is virtually insoluble in water and can thus be separated from water mechanically in suitable effluent treatment plants.

12.3 Bioaccumulation:The product will not be readily bioavailable due to its consistency and insolubility in water.

13. Disposal considerations

13.1 Product:In accordance with local and national regulations. Should not be released into the environment. Do not contaminate ponds, waterways or ditches with chemical or used container.

13.2 Uncleaned packaging:Packaging material has to be emptied completely and disposed in accordance with the regulations. Packaging can be recycled if not contaminated.

14. Transport information

14.1 Transport regulations:Not classified as hazardous under transport regulations DOT, ICAO/IATA, IMDG/GGVSee, ICAO/IATA

15. Regulatory information

15.1 U.S. Toxic Substances Control Act (TSCA):Complies

15.2 SARA 313:This product does not contain any chemicals which are subject to the reporting requirements of the ACT and Title 40 of the Code of Federal Regulations, Part 372.

16. Other information

16.1 NFPA Hazard codes: Health: 1, Flammability: 1, Reactivity: 0

16.2 HMIS III Rating: Health: 1, Flammability: 1, Physical hazard: 0

This data is based on the current state of our information and experience. This safety data sheet describes our product in terms of safety requirements. Preceding data is not applicable as a warranty of product properties. It is the responsibility of the recipient to observe the existing legal regulations for the use of this product.

Disclaimer: The safety data contained on this data sheet is furnished without charge or obligation and accepted at the recipient's sole risk. This data describes our product in terms of safety requirements. The data provided is not applicable as a warranty of product properties. It is the responsibility of the recipient to observe the existing legal regulations for the use of this product.